Application and function of pumps in the chemical industry

When it comes to chemical substances, choosing the perfect pump plays one of the most important roles.

.jpg)

Die chemical industry Is an important part of the German economy. It includes the production and processing of chemical products. The chemical industry is a very diverse sector of the economy. In Germany, around 4,000 companies are active in this sector. They employ more than one million people and generated a turnover of Over 200 billion euros.

Chemical industry definition

Die chemical industry Deals with the production of chemical substances. This sector produces materials for other industries. Important examples include the food industry, automotive industry, plastics industry, mechanical engineering, building materials manufacturers and the glass industry. Products that fall under the chemical industry classification include organic and inorganic chemicals, plastics, pharmaceutical products and fertilizers. This also includes soaps, Detergents, Glues and many other chemical products.

Zu unseren Pumpen für die Chemieindustrie

What belongs to the chemical industry?

Promoting corrosive, aggressive or otherwise challenging properties generally includes the chemical industry. These substances can vegetal, are of animal or mineral origin. This includes cleaning processes and loading processes from tanks or production plants, for example. In addition, individual dosing and transfer of chemical substances.

Examples of typical chemical conveying media are acids, such as nitric acid or hydrochloric acid, hydrocarbon, ammonia, or paints and varnishes.

A distinction is made between three different processes in the chemical industry. For example, there is the extraction. Extraction makes it possible to separate both liquid and solid substances using a solvent. Second, there is the process of workmanship, which processes the substances into the desired end product. The third method is the transformation. With the help of chemical reactions, products are produced which differ in the chemical properties of the starting material.

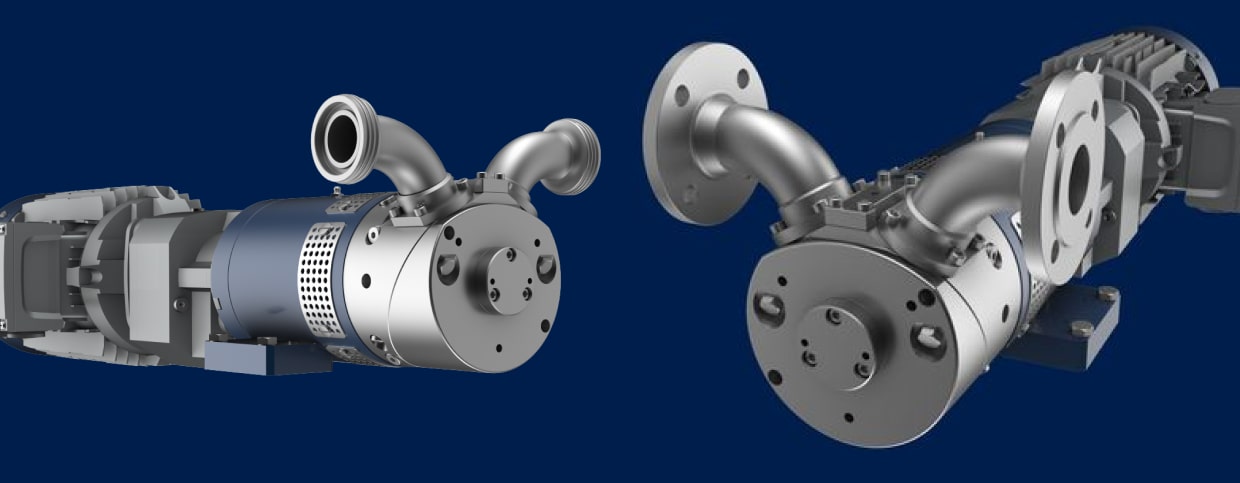

Which pumps are suitable for chemicals?

When it comes to chemical substances, choosing the perfect pump plays one of the most important roles. Appropriate funding for chemical plants For example, are horizontal centrifugal pumps. These transport highly aggressive media, such as acids, and keep the medium circulating. They enable rapid emptying and are available with different conveying capacities.

Also suitable for chemical plants are magnetic centrifugal pumps. As the name suggests, magnetic centrifugal pumps use the forces of attraction and repulsion between two permanent magnets on both sides of pump and enable a contactless transmission.

radial pumps, belong to the centrifugal pumps and are most commonly used in chemistry. They convey radially, which means that pumping medium enters and is promoted by a bike. It then emerges vertically again through a spiral housing.

Are easily conveyable Liquids containing gas through a side channel pump. It combines centrifugal and positive displacement pumps in one.

Examples of conveyable media from the side channel pump are petrol and diesel, but also volatile chemicals, such as butadiene or even water and steam condensates.

Highly viscous liquids, sludges, containing solids Media is best used by eccentric snails promoted. It is one of the positive displacement pumps, which means that they pump the medium into a room and then displace it from there again.

The efficiency of rotary lobe pumps For example, is higher than that of positive displacement pumps. This saves energy and costs. They transport lubricating as well as non-lubricating substances and are easy to handle and operate.

Also our wobble ring pump, an innovative type of positive displacement pump, is suitable for pumping chemical substances. In this way, it makes it easier to promote colors and Lacken and impresses with its easy cleaning. It is just as relevant for pharmaceutical market and the cosmetics and food industry. It features easy adjustment of the delivery direction, selectable connection types and pump orientation. It is FDA compliant and therefore food genuine, ATEX certified and standardized according to EN 60204-1. We offer you a flexible pump and the opportunity to advise you. Our wobble ring pump is also available for rent in all sizes.

How long has chemistry existed?

Chemistry as a natural science emerged in the 17th and 18th centuries. It originated in ancient times. Back then, the processes were based on pure experience. This process is called metallurgy. Metallurgy generally involves the extraction and use of metals. With the integration of astrology and an esoteric world understanding, the alchemy. Alchemists researched and converted substances and thus laid the building blocks for today's chemistry.

The main benefit of alchemy was to find the Philosopher's Stone and the elixir of life. Around the 12th century, an alchemy boom broke out and as a result, the subject areas of alchemy are becoming more and more prominent. The years and knowledge of these two areas paved the way for pharmaceutical production in the 16th century. This was followed by electrochemistry, color chemistry, polymer chemistry and many more.

In the 19th century, the rise of chemical production, as a focus of industrial mode of production. However, this had some consequences. As a result of the lack of thought about occupational or environmental protection measures, the health of humans, animals and, in particular, environmental huge.

But in today's times of energy crisis, the chemical industry can help us. By producing green hydrogen, Natural gas bottlenecks can be easily overcome. Do you believe some scientists, so could heating with fossil raw materials They will soon be a thing of the past.

Do you disassemble hydrogen With an electrolyzer in its individual parts, namely hydrogen and oxygen, you get green hydrogen. This electrolysis process is driven by renewables. Green hydrogen can now be used in a variety of ways, for example for generating heat, as an energy source in an electricity system or even in transport. The chemical industry also benefits from green hydrogen. Die Hydrogen production provides important components for steel production or for the production of basic chemical products.

Germany's current energy mix consists of nuclear energy, fossil fuels and renewable energy sources. Include fossil fuels petroleum or coal and renewable energy sources such as wind power or solar energy. To make us more independent of big energy companies, we should consider switching to purely renewable energy sources. Green hydrogen appears to be a good way to do this.

What do chemical companies produce?

A wide range of products provides the chemical industry Here. Sometimes we don't directly notice anything about it. As a result, the most important substances that are manufactured specialty chemicals are for further processing. The most important customers for this are plastics processor and the automotive, packaging and construction industries. Only around 30 percent reach the end user directly.

You can find out more about the application and function of water pumps in the following items learn.

Do you have any questions?

Please feel free to get in touch with us. For example, via our contact form or telephonic during our opening hours.